IRON Systems: Laser-Marked QR Codes for Industrial Traceability, Efficiency, and Safety

In an increasingly automated industrial world, where efficiency and safety are top priorities, product and component traceability has become essential. But how can you ensure clear, durable, and permanently readable identification? One of the most innovative and effective solutions is laser marking QR codes on metal tags, a technology that eliminates the limitations of adhesive labels and traditional printing, offering a permanent, tamper-proof marking method.

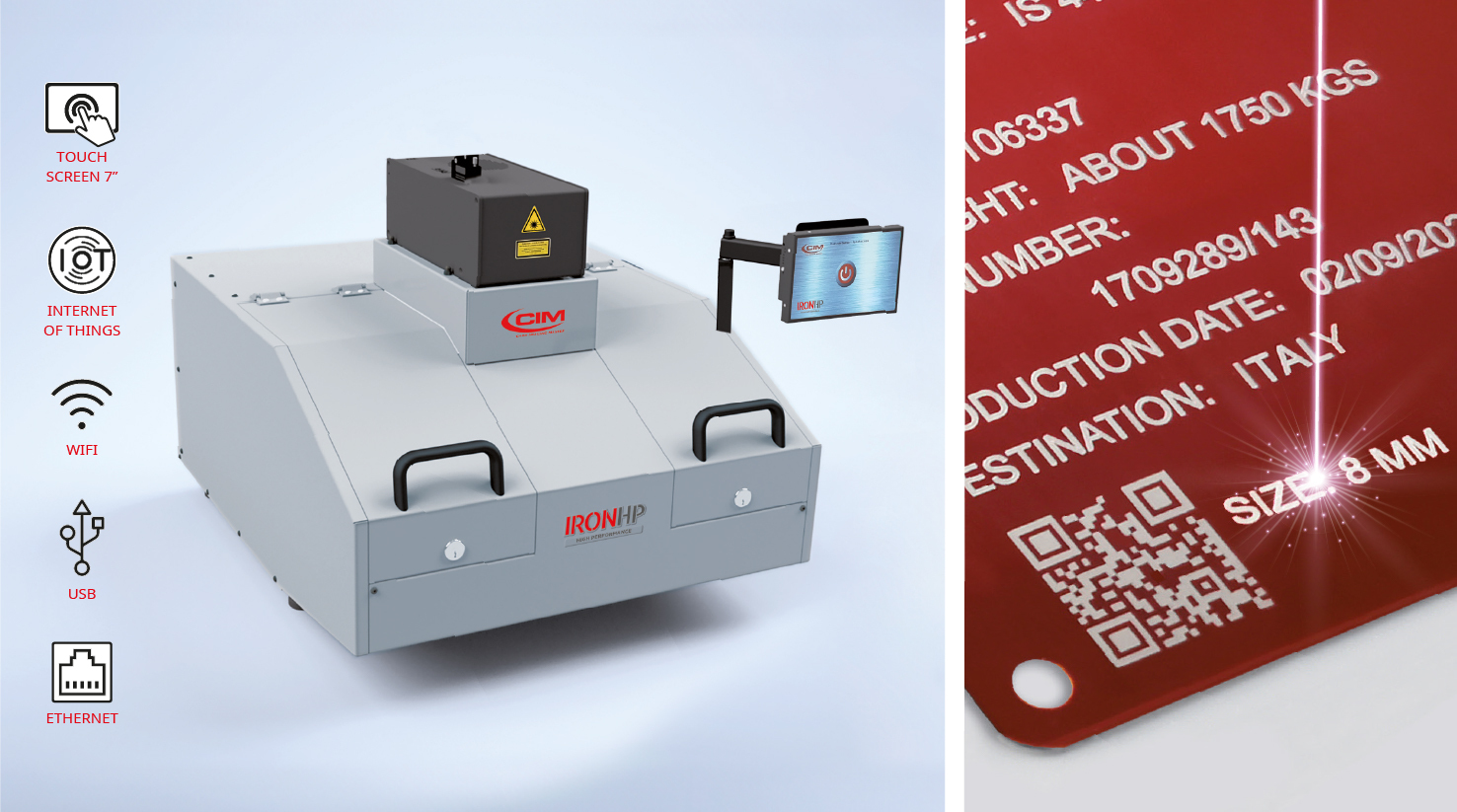

With IRON Systems, it is possible to create laser-marked QR codes on stainless steel and aluminum tags, ensuring excellent readability and high resistance to extreme temperatures, chemicals, abrasion, and wear. This means that, regardless of the environment—from manufacturing to aerospace—the QR codes remain fully readable, enhancing production management and workplace safety.

Why Are Laser-Marked QR Codes the Ideal Solution?

In industrial environments, QR codes have become a key tool for optimizing processes, reducing intervention times, and ensuring continuous monitoring. A simple scan provides instant access to technical data, assembly diagrams, quality certifications, and more—minimizing errors and streamlining workflows.

But the benefits don’t stop there:

• Instant traceability – Each component can be tracked at every stage of the production process, from manufacturing to delivery.

• Optimized maintenance management – Technicians can scan the QR code on machinery and equipment to instantly access digital manuals, instructions, and maintenance history—eliminating the hassle of searching for paper documents.

• Enhanced safety and compliance – Laser-marked QR codes can store critical safety procedures, emergency protocols, and industry regulations, helping to reduce risks and improve corporate compliance.

• Unmatched durability – Anodized and laser-marked QR code tags do not deteriorate over time and withstand harsh environments without fading or wearing out.

Additionally, these metal tags can be customized to meet specific company needs: available in various sizes, color-coded for better visibility, and pre-drilled for easy mounting, ensuring seamless integration with any machinery or surface.

IRON Systems: Laser Technology for Extremely Readable QR Codes

For clear, readable, and long-lasting QR codes, advanced marking technology is essential. IRON System was designed precisely for this purpose: leveraging DPSS laser technology, it allows precise engraving of QR codes, text, logos, and serial numbers on metal tags, delivering top-quality results.

What Makes IRON System Truly Unique?

• Versatility – You can adjust the depth and sharpness of the engraving to suit various surfaces and materials.

• Precision – Every engraving is perfectly readable, even on irregular or small surfaces.

• Extreme resistance – Markings remain intact even in high-temperature environments, chemical exposure, or heavy wear conditions.

• Adaptability – Whether working with aluminum or stainless steel tags, IRON System ensures flawless engravings every time.

• Integration into production processes – Easy and fast integration with company systems allows for a seamless workflow.

Thanks to this technology, each laser-engraved QR code becomes a true smart management tool, capable of optimizing the entire product lifecycle—from production to maintenance.